Electronic Discharge Machining

Electronic Discharge Machining is a process in which a steel block (which will become the production mold) is submerged in an electrolyte solution. The electrode is slowly plunged down onto the steel, which "blasts" away at the material until what remains is a cavity in the shape of the electrode. The electrolyte solution helps carry the charge from the electrode to the steel and also helps carry the metal "dust" away from the work surface. Over a substantial period of time (probably 10 hours in this case) what remains is a block of steel that has this exact shape cut into it. All the dust-sized fragments of metal that used to be in this cavity are captured in the machine's filtration system and looks much like sludge. Multiple electrodes are used since they do wear out over time, but the result is a detailed shape in steel that did not require traditional cutting methods.

See also:

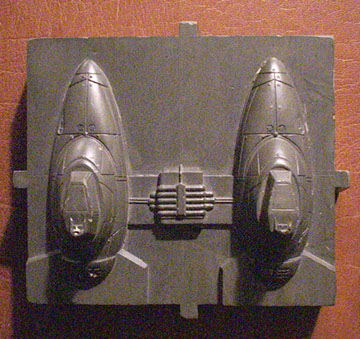

Tooling Aids for Die-Cast Cloud Car

Description: Chris Georgoulias