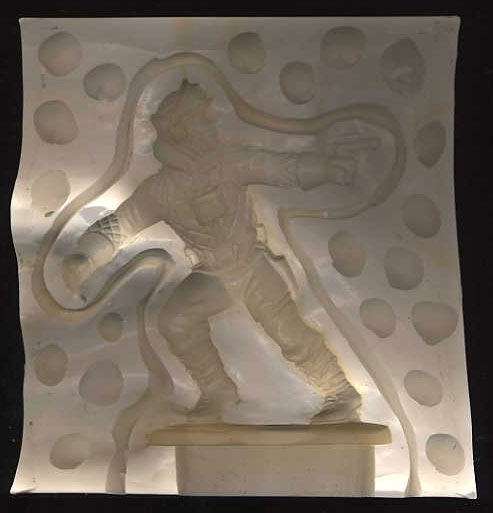

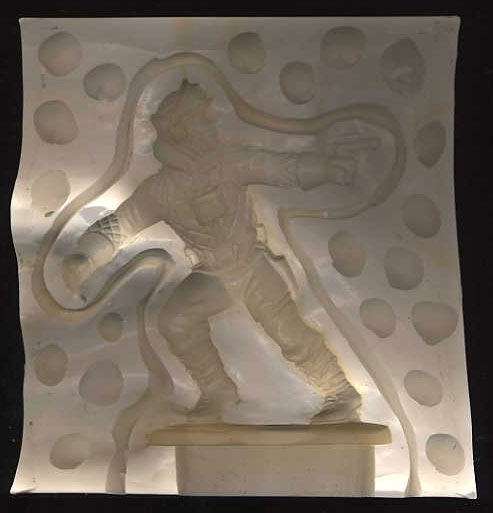

Silicone Mold for Micro Collection Luke Hoth Figure: Hardcopies, or prototypes made from hand-poured urethane casting agents, are made using silicone molds much like the one you see here. Generally, these molds are created using the original sculpting of whatever item is being developed. In making the mold, the model maker lays the original sculpt in a horizontal position and imbeds it in clay up to its mid-way point. The line the surface of this clay comprises forms what is known as the "parting line." In most cases, this parting line is carefully delineated before silicone molds are made; wax sculptings often will bear pencil-drawn lines reflecting where the model maker has determined the parting lines should be. With the sculpt half-buried in clay, a slight retaining wall is built around the piece its clay bed, and a silicone mold-making mixture is poured over it. Once this mixture has set, the clay is removed. What remains is a silcone mold half, in which is buried one half of the original sculpting. To create the second mold half, a mold release is applied to the silicone surrounding the sculpt, and another layer of silicone is poured over the half of the sculpt that remains exposed. After this second layer sets, the two silicone mold halves can be parted and the sculpt removed, What remains is a two-part silicone block, with a negative impression of the sculpt inside of it.

You'll notice that there are quite a few conical shapes evident in the surface of the silicone. These are known as "keys." They allow for the mold halves to be joined properly once the mold is finished and prevent it from slipping out of joint. In the case of the mold you see here, the keys were probably made by the mold maker cutting the conical shapes into the solidified silicone of the first mold half. Then, when the second portion of silicone was poured over it, the liquid material seeped into these depressions and formed corresponding pyramids in the second mold half. As these pyramids fit perfectly into the conical depressions of the opposite half, they provided for an efficient key system. The mold maker employed by Kenner during the early '80s seems to have utilized a number of different key systems, this being one of the earlier ones.

You've also probably noticed the channels extending from certain points of the mold cavity to the perimeters of the mold material. These were cut to allow air to escape from certain extremities of the mold's details. Without them, air pockets would form in these areas and create flaws in the hardcopy product.

Very few of these silicone mold pieces seem to have survived, and all that I know of are in the hands of collectors. However, it has been speculated that the rash of blue urethane fake hardcopies that hit the market in the early '90s was caused by counterfeiters using similar molds still in storage at Kenner.

Description: Ron Salvatore